Phoenix heat 110+ degrees for 31 consecutive days

Record-breaking heat waves scorched southwestern states this summer concert season. Phoenix had 31 consecutive days of temperatures above 110°F from June 30 to July 30—breaking the previous record of 18 days set in 1974. Extreme temperatures increase the risk of heat-related illness during stadium show load-ins – and Rhino Staging is no exception. Don’t worry! This rescue story has a cool, happy ending.

Heat Stress Affects Live Events Workers

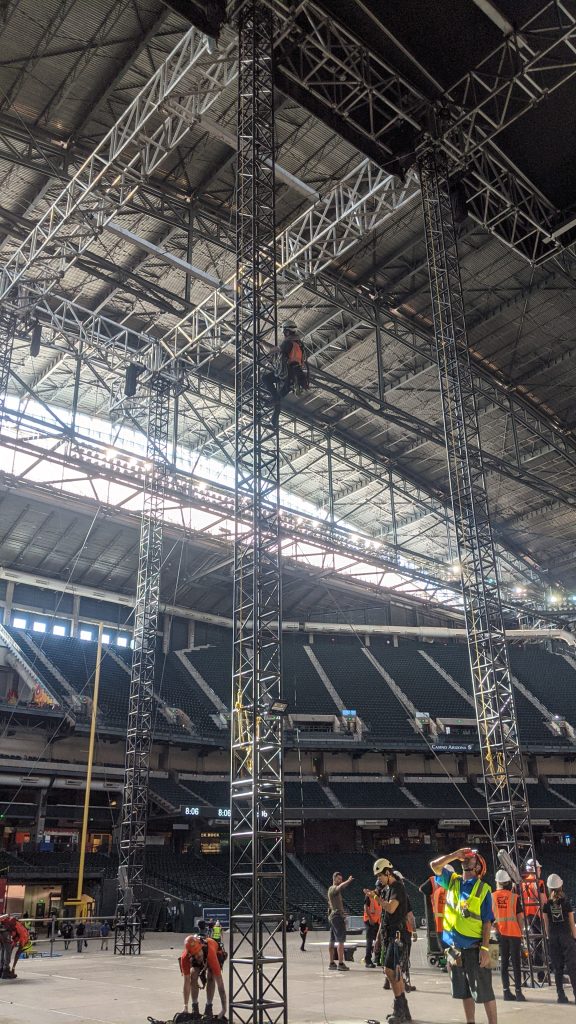

During a stadium show load-in at Chase Field, the heat was on! Luckily, the closed stadium roof provided shade for the stagehands and riggers setting up the show. Direct sunlight would have raised the conductive heat temperatures on the black stage deck to dangerous levels. Even so, the vinyl roof skin on the metal concert stage roof system still traps heat. Not so good for production riggers…

Production Rigger Overheats In Rigging Grid

While working at height, a rigger began to experience signs and symptoms of heat illness. At one point, the rigger briefly passed out. Since they were already sitting in their work positioner – a Petzl Grillon – there was no free fall into the fall arrest device that connected to the roof structure. The Rhino Staging rigging team sprang into action to provide for prompt rescue. Fortunately, the affected rigger regained consciousness, turning this situation into an assisted rescue.

Stage Roof Rigging Grid Assisted Rescue

The affected rigger remained clipped into a self-retracting lanyard (SRL) as their backup device. The rescuers put the affected worker on belay, then wrapped that rigging rope several times around a large truss chord. These wraps create friction to allow for a smooth and controlled descent.

During the lowering process, one rescuer managed the rigging rope while the other rescuer climbed alongside the affected rigger to help them down the tower truss. Strong communication prevailed during the entire operation as the rescuers provided constant commands and confirmation responses until the affected rigger landed safely on the ground.

Once the affected rigger safely reached the ground, a ground rigger immediately began standard first aid protocol. The affected rigger felt hot, fatigued, and physically weakened. The good news is they were conscious and spoke coherently. After resting in a cool area and drinking water, the affected rigger regained strength and completed an incident report. They felt well enough to help with the load-out a few hours later as a ground rigger.

Root Cause Analysis And Safety Debrief

Our root cause analysis identifies the following contributors to this incident:

- Peak temperatures outside almost reached 120°F.

- Roof skins trap heat and reduce airflow.

- Rigging is a strenuous activity that can contribute to increased body temperature, depleted electrolytes, and dehydration.

After handling the incident, Rhino Staging supervisors conducted a safety debrief to discuss what happened and preventative measures. They emphasized the importance of hydration and that the hydration process must begin days before working in high heat. They also expressed that while the “tough it out” mentality is common, we must respect our physical limitations and give our bodies what they need before a situation becomes worse.

What Can Workers Do?

Here are some tips for stagehands and riggers working outside in high temperatures:

- Take cool-down rests when necessary.

- Hydrate a day before working in the heat.

- Avoid drinking alcohol within 24 hours of working in the heat.

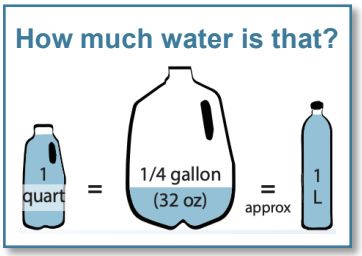

- Drink 1 cup (8 oz.) of water every 15-20 minutes – That’s 32 oz. per hour!

- Use cold, wet evaporative cooling towels on the head and neck to help stay cool.

- Immediately report symptoms or signs of heat illness in yourself or in others.

What Can Leaders Do?

Supervisors and production leads play a crucial role in promoting heat safety. Once supervisors realized that the heat was getting to the riggers, they sent water up to them and encouraged them to come down and take breaks as needed.

Check out the more tips for leaders:

- Encourage the crew to drink plenty of water.

- Ensure cool water is available at all times.

- Remind the crew of their right to take a cool-down rest when necessary.

- Monitor crew for signs of heat illness.

- Take immediate action if any signs or symptoms of heat illness are observed or reported.

Technical Rescue Success And A Job Well Done!

We are extremely proud of how well our riggers handled this incident! The rescue was executed with such an amazing amount of grace and lack of panic that it happened virtually unnoticed by stagehands and tour personnel working on the stage deck.

Even with this being an emergency situation, the rescue was done discreetly and without sounding alarm bells. The rescuers did an awesome job of using the resources that they had on hand, in a safe and effective manner, and managed to safely lower the affected rigger out of the rigging grid without making a fuss, without creating a panic, and without drawing attention to the situation. The rescuers also created a simple, yet effective, system to get the affected rigger down; just a rope with a couple of wraps around the truss and an SRL, with someone climbing down to assist. A very elegant solution and an example of what to do in this type of situation.

Thank you to everyone involved in this incident for your quick thinking and appropriate actions. We appreciate you!